SO WHERE DID IT ALL BEGIN?

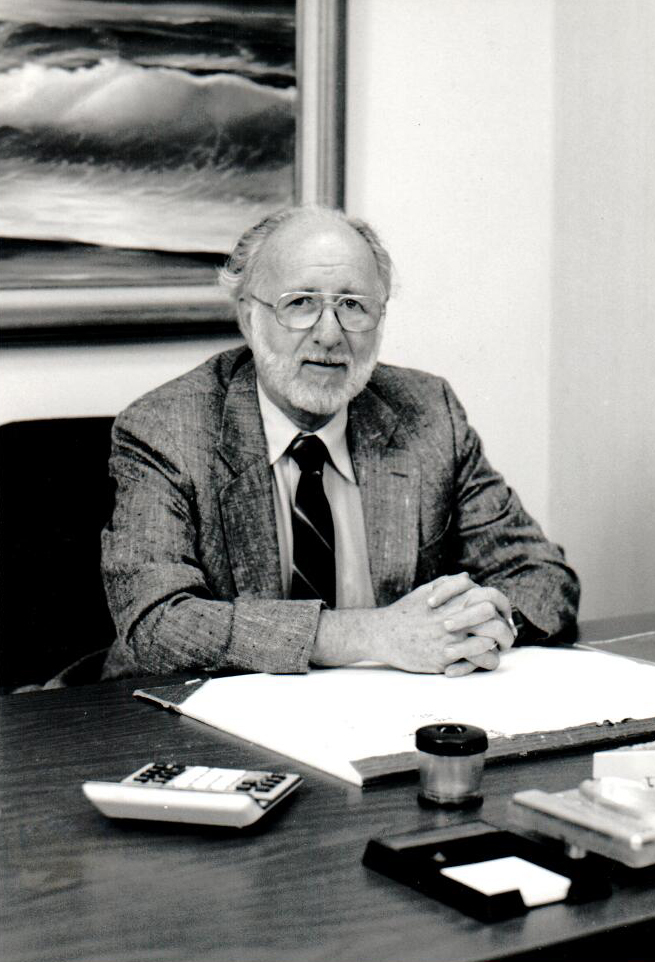

Our story begins with Band Saws. Harris Engineering and Manufacturing, also known as HE&M Saw, was founded by Gerald Harris in January of 1964. With a background in engineering and tool instrument training, Harris began acquiring first-hand knowledge of various machines during the post-World War II industrial boom.

Over the next 50+ years, HE&M Saw became the leading manufacturer of industrial band saws. HE&M Saw continues to revolutionize the band saw industry with more patented innovations than any other manufacturer. Innovations such as Blade Enhancers, Cut Watcher, multi-guide arm saws, full stroking stacking clamps and computer controlled saws make HE&M Saw the industry leader.

HE&M MATERIALS HANDLING EVOLUTION

During the 1980s, we took notice that our Band Saw customers were beginning to request an evaluation of their Material Handling systems. This request typically came with the installation of a new HE&M Saw and the resulting impact on the customer’s raw material flow. The installation of a new Band Saw will often highlight any Material Handling inefficiencies; due to certain aspects of the system not being able to leverage the efficiency of the new Band Saw.

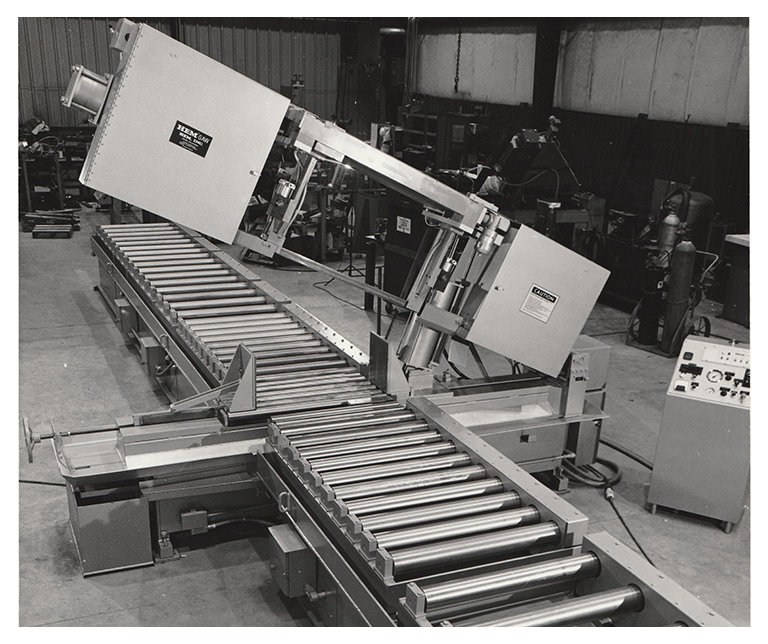

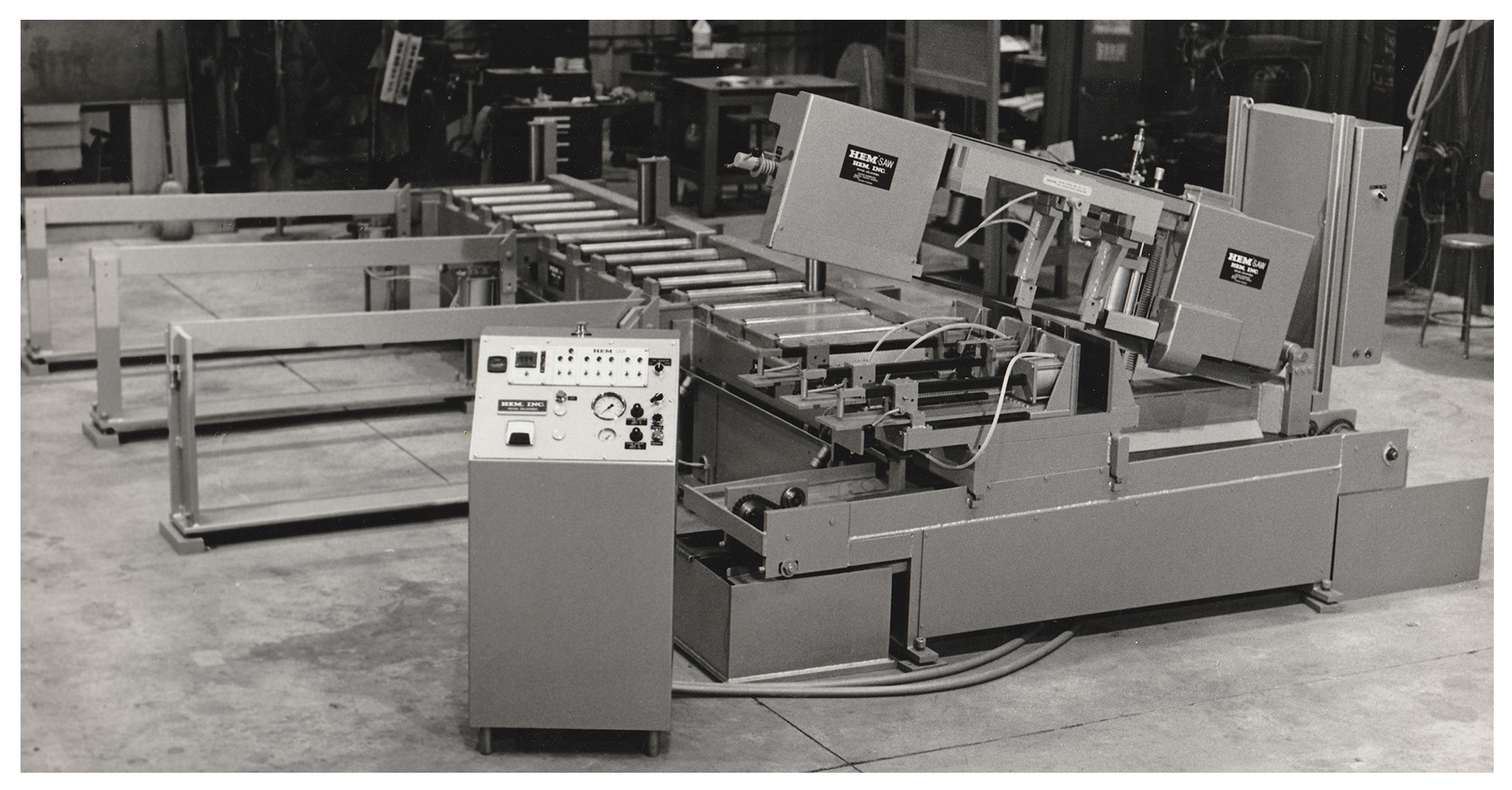

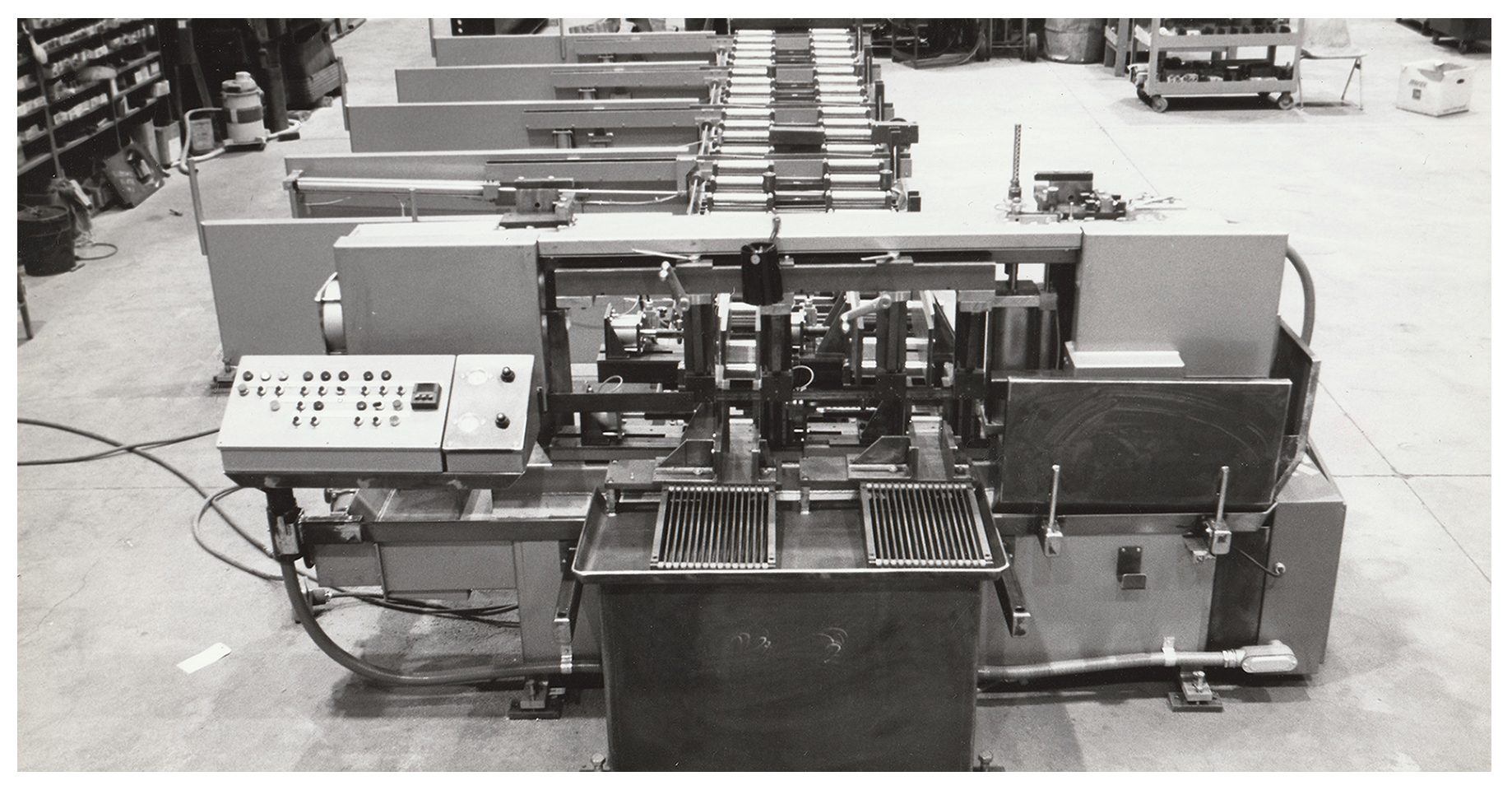

Our early work began in the 1980s with our design of improved side loaders and conveyor systems. This soon evolved into more complex systems such as the transfer lift and carry and the cross conveyors with extensive controls and monitoring systems. HE&M Material Handling can now provide an assessment of our customer’s entire system of moving raw materials.

We have evolved to an in-house team of over 15 engineers allowing for a collaborative approach when it comes to developing Material Handling systems for our customers. In addition to the newer engineering resources on our team, we have engineers with decades of experience possessing a deep understanding of how metals are milled and how the older systems process raw materials.

The next generation of computer controlled Band Saws are more accurate and efficient, compensating for more variables. In order to leverage the new saw’s efficiencies, we often find the material handling systems before and after the Band Saw, will need to be improved, in order to improve the overall material flow process.

HOW DO WE MEASURE UP?

As our company’s founder once told us, you can take 10 tape measures and they will each measure differently. Precise and continuous measuring and calibration is an integral part of every system we engineer. Getting the “right cut” depends on a lot of variables, including the thermal expansion of metal and how all the various controls and continuous measuring work together. An inefficient system will struggle to cut a 40ft steel I-beam within an accuracy of 1/4th of an inch, let alone at 1/16th of an inch. HE&M Material Handling is a leader in designing highly accurate and efficient material handling systems

We take an entire systems approach, often leading to other material flow improvements, and thus helping our customers MOVE MORE STEEL.