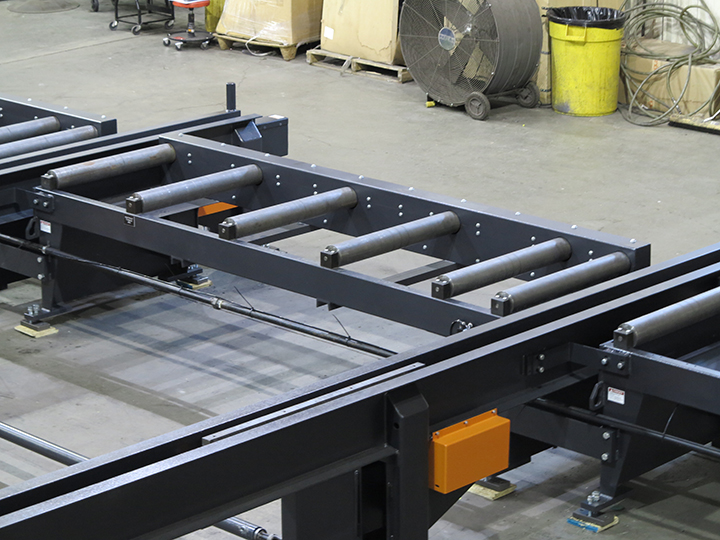

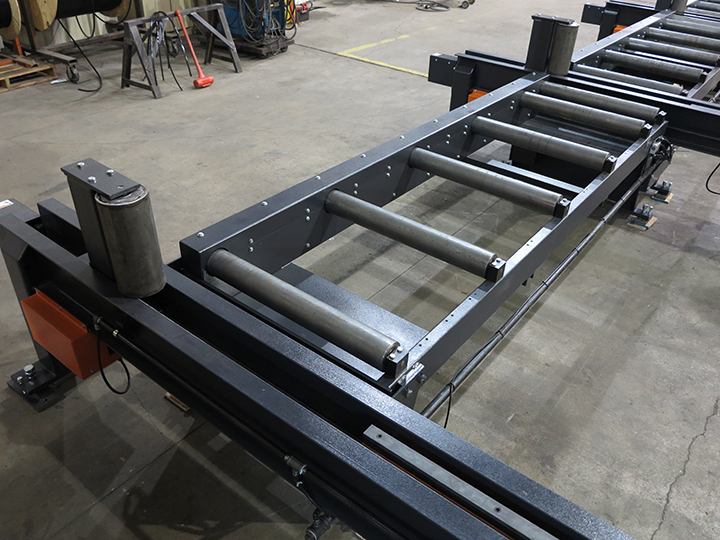

STAGE 2 CONVEYORS

Powered tabling system on 12”centers to move the heaviest of material through saw. Stage II Conveyors are offered as either an idle conveyor or a powered conveyor.

Roller Size:

3-1/2" - 4” diameter x .312” wall DOM tubing on 12” or 24” Roller Centers (Width is either 22", 29”, 34", 40”, or 46” depending on Saw Model)

Section Sizes:

3', 5’ or 10’

Description:

- Conveyor load capacity is 10,000 lbs. per table, 2,000 lbs. per roller.

- For each roller, class 5 precision, hardened and ground sealed bearings are used for long-term trouble free use. On the powered conveyor, we use one continuous #60 chain for each section of conveyor. The roller shafts are mounted in pillow blocks for precision roller-to-roller alignment.

- The frames are made with 6” x 2” x 3/16” wall rectangular structural tubing giving more strength than the customary channel iron frames.

- The legs are fabricated with foot bars that sit on leveling pads with approximately 1-1/2” of vertical adjustment. The leveling pads can be anchored to the floor.

- Powered conveyors are controlled by a free-standing pedestal console with a joystick that controls the conveyors in and out.

- Powered conveyors have 5 HP motors controlled by a Variable Frequency Drive and a gear reducer that drives the rollers. The speed is variable to 50 FPM max forward and reverse.

- If powered, the automatic saws have conveyors with in-feed rollers that clutched or controlled with a “roller-assist” mode for the indexing of larger loads. The out-feed rollers are clutched.

- Pricing includes all fittings, couplings, and wiring for the installation.

- HE&M Saw ships conveyors in complete sections, NOT “Erector Set” style, reducing typical installation costs by 2/3rd.

These conveyors can be used with H130H, Hurricane, H130-DC, DC20, CT2000, H160-DC through H3236, all Wide Flange, and all Vertical Series.

These conveyors can be used with cross transfers.

Example System: Split Cross Transfer Systems

Two-way transfer enables staging from opposite conveyor while material is processed through the saw.

MOVEABLE TABLING SECTION:

Description:

- For horizontal miter saw models such as the Hurricane and WF190MRB, it’s sometimes necessary to employ a small section of roll-in-roll-out tabling next to the saw to allow the saw structure to move into position. These saw sections are on tracks to make the adjustment quick & easy.